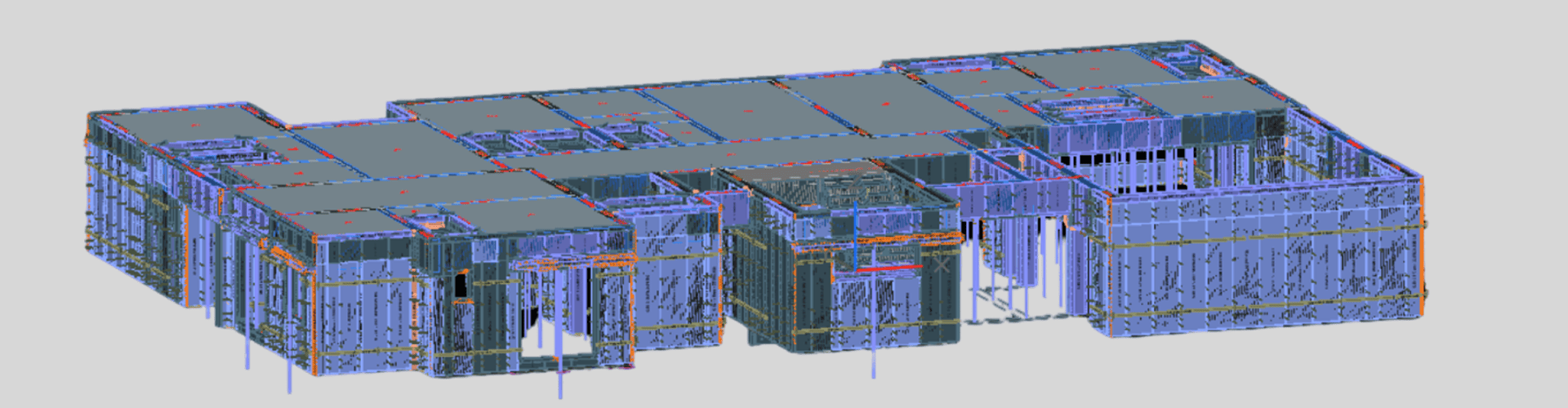

We utilize a powerful 3D BIM-based software that enables precise aluminum formwork design. This not only enhances accuracy at the design stage but with inbuilt checking feature, it also adds an extra layer of validation before production or installation. The result? Maximum accuracy, faster execution, and better outcomes.

Rapid design delivery after shell plan approval.

Highly precise and accurate 3D modeling.

Refined design for smooth manufacturing & installation.

Significant reduction on site and production errors.

Built-in checking tools (Collision, Leakage, Hole matching and Wall tie slot) for pre-production checks.

Faster, more reliable, and efficient design output.

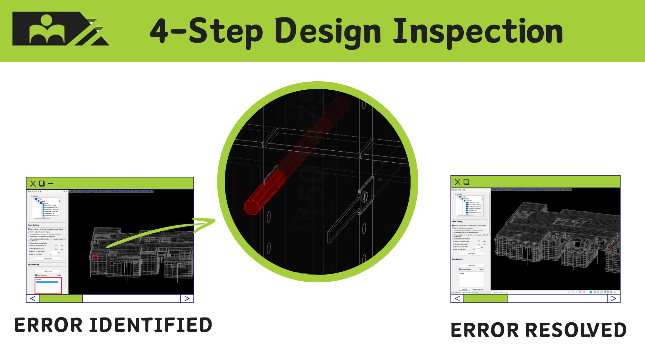

Our design process features a built-in 4-step automated quality check to ensure maximum accuracy before production begins. This includes:

Collision Detection

Identifies

overlapping or clashing elements in the 3D model.

Leakage Check

Verifies design

closure to avoid gaps that could cause concrete leakage.

Hole Matching

Ensures perfect

alignment of holes across connecting panels.

Wall Tie Slot Accuracy

Confirms

precise positioning of wall tie slots for structural integrity.

By detecting and resolving potential issues during the design stage, we significantly reduce on-site rework, material wastage, and project delays—leading to faster, smoother execution.

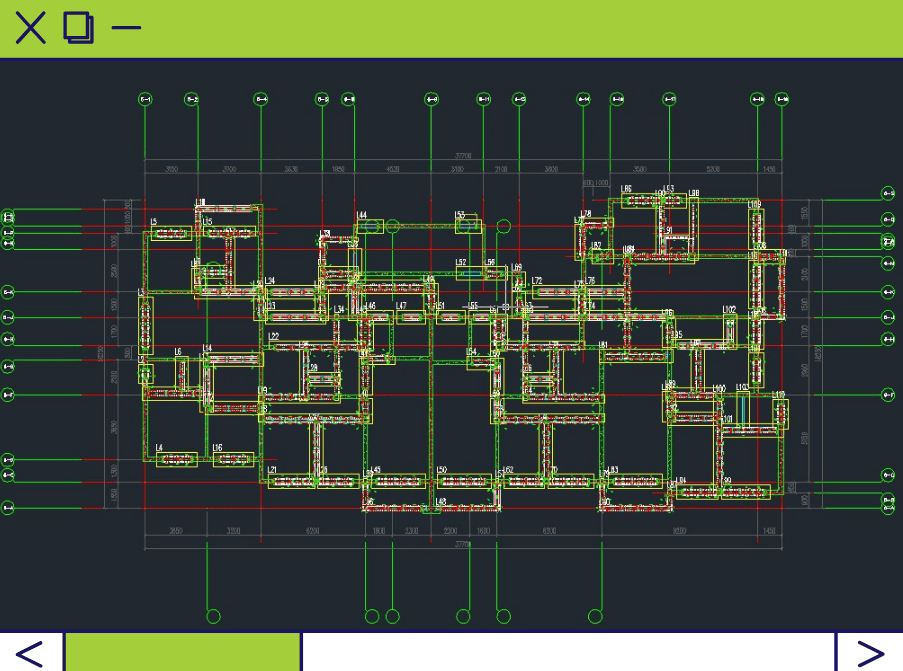

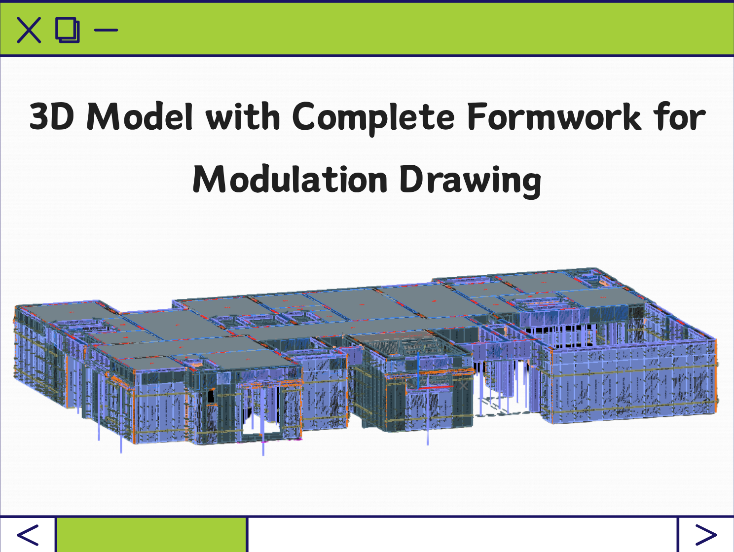

Modulation drawings are detailed layout drawings that define the size, type, quantity, and placement of aluminum formwork panels as per the structural layout. Generated directly from the 3D model, these drawings show how each panel fits within the wall, slab, or beam system.

These drawings are essential for mock-up planning, pre-construction checks, and communicating design intent to site engineers and supervisors. They also assist in visualizing casting sequences and improving installation efficiency. With clearly labeled dimensions and panel IDs, these drawings reduce confusion on-site, minimize installation errors, and act as a critical bridge between design and execution.

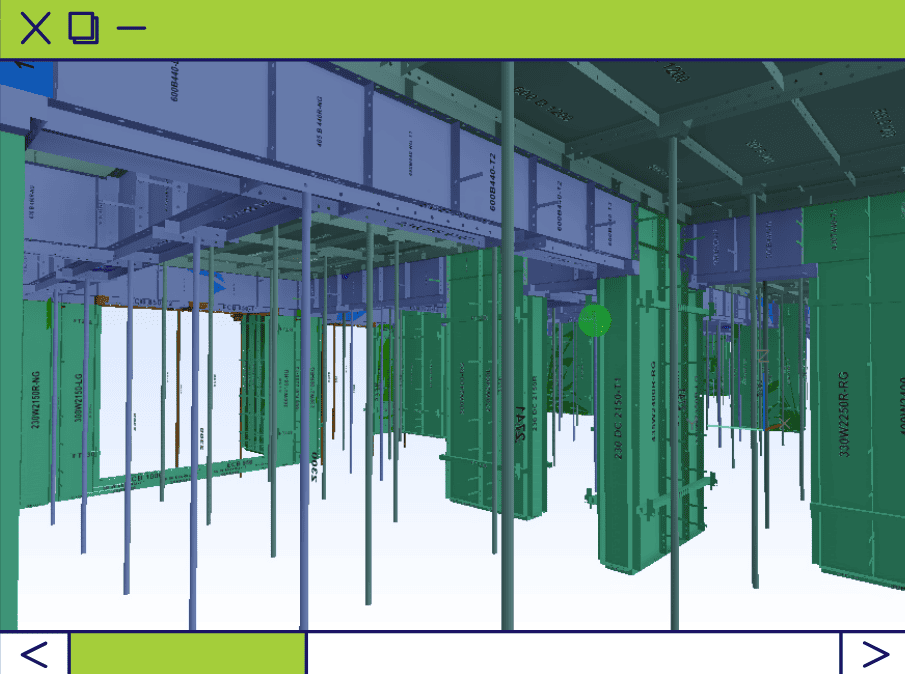

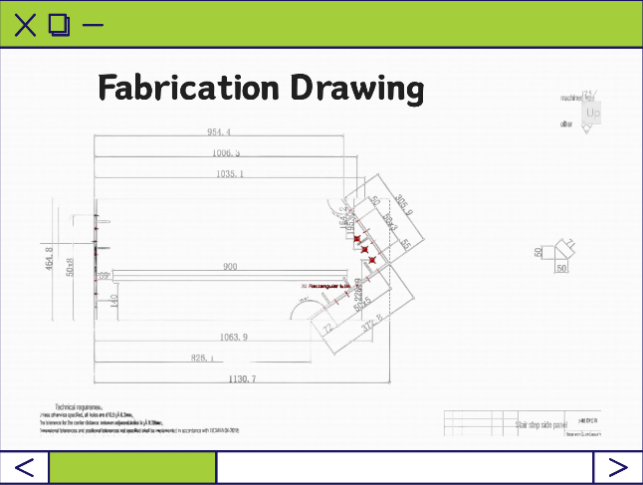

Fabrication drawings provide detailed, panel-wise specifications required for manufacturing each aluminum formwork component. Generated automatically from the 3D model, these drawings include exact dimensions, panel codes, holes, slots, etc. Every panel, even with slight variations, receives its own unique fabrication drawing, eliminating guesswork and reducing manual drafting errors.

These drawings ensure that production teams manufacture components precisely as intended, maintaining tight tolerances and high quality. They also help identify standard vs. non-standard panels, aiding in batching and material planning. By streamlining communication between designers and production team; precise fabrication drawings improve production accuracy, reduce rework, and save time, ensuring that each panel fits seamlessly during site installation.

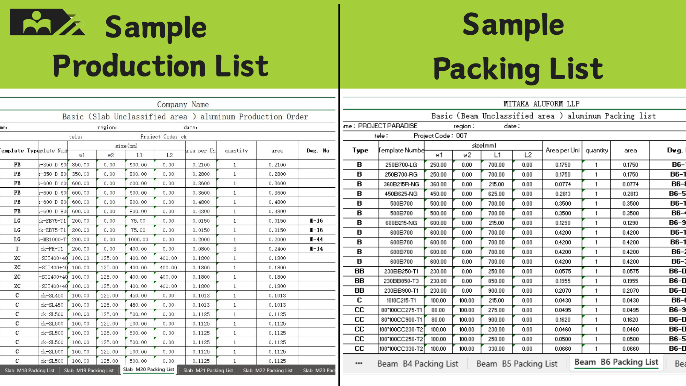

Production and packing lists are auto-generated from the 3D model and provide a complete breakdown of all panels and accessories required for a project. These lists include item-wise details such as panel ID, quantity, size, type, and associated components like wall ties, pins, wedges, and supports.

Packing lists are organized single unit-wise, they help track material requirements accurately and ensure nothing is missed during dispatch. The production list supports the factory in planning tasks efficiently, while the packing list guides the logistics team in organizing materials systematically for transport. Together, these lists improve quantity control, reduce wastage, and streamline coordination between design, production, and site teams ensuring the right materials reach the site, ready for smooth installation.

At Mitaka Design, we believe smart design is the foundation of efficient construction. Our services are built to save you time, reduce errors, and deliver accuracy from the very first step. With advanced tools like 3D BIMBase software and expert team, we transform your shell plans into actionable, production-ready outputs. Whether it’s a single tower or a large-scale project, our team ensures every design detail supports smooth execution on site. Partner with us for faster, smarter, and more reliable formwork delivery.